Roof elements

View products

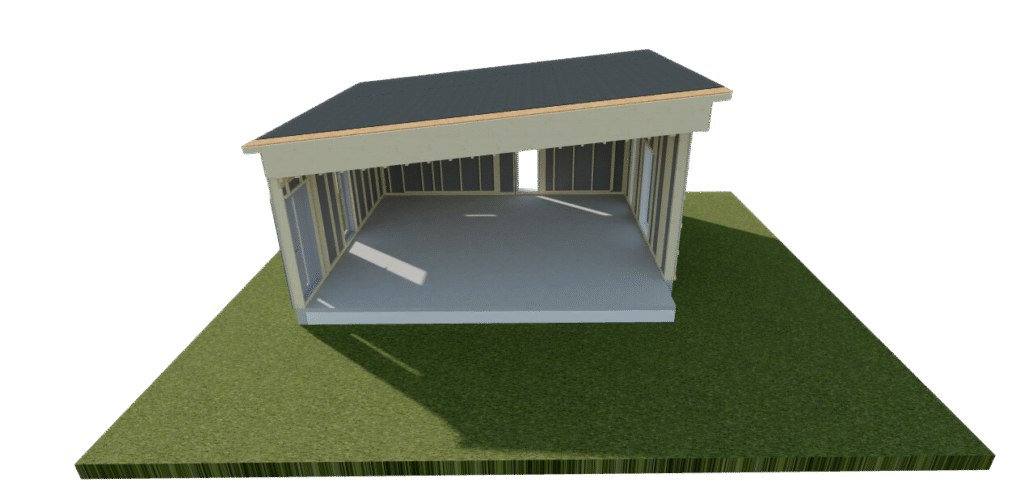

WARM SLOPED ROOF ELEMENT

This roof is suitable for Finnish fire class P3 buildings from detached houses to terraced houses. The roof can be completed with eaves, small animal nets and fire compartments. The roof can be implemented as a sloped roof or as a gable roof by using a ridge beam.

Structure:

Underlay

18mm OSB

100mm ventilation gap

Load-bearing structure + mineral wool

Vapour barrier (plastic)

48mm battening, 400mm centres

Technical characteristics: U value 0.09W/m2K, element weight 0.6kN/m2, maximum element size 2.4m x 12.4m.

Precision of manufacture in conformance with SFS5978.

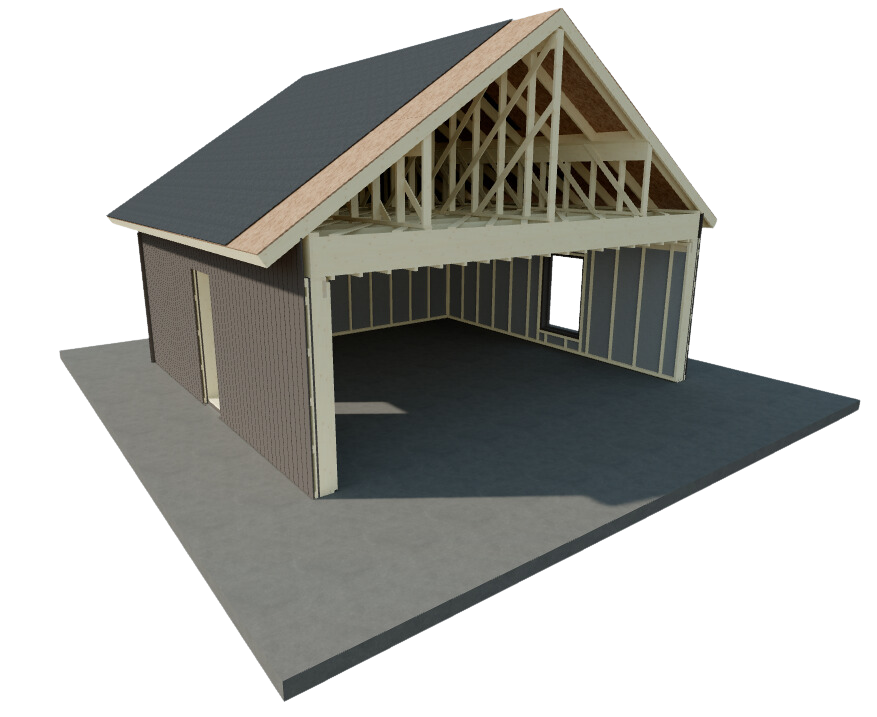

WARM GABLE ROOF SYSTEM

The gable roof system consists of three element products:

1) CEILING ELEMENT YP

The ceiling element can be used to equip the building with a warm wall head. Support elements and a cold roof can be installed on top of it, so that the roof of the building can be finished quickly. Sarking boards, work surfaces, and support element lower guide timbers Load-bearing frame according to structural plans

Structure:

100mm mineral wool (loose wool on site)

Vapour barrier (plastic)

48×48 battening, 400mm centres

2) SUPPORT ELEMENT TK

Support elements are installed below the cold roof in the shape of the building’s roof. Support elements are supported on top of a concrete frame or ceiling elements. The support element can also be prefabricated as a compartmented version.

Structure:

42×98-198 frame C249mm

Wind barrier plasterboard or sarking boards

3) COLD ROOF KK

The roof is installed on top of a load-bearing concrete frame or ceiling elements so that it is supported by the support elements. Weight 0.3kN/m2.

Structure:

Underlay TL2

18 mm OSB

42×123-42×198 load-bearing structure according to structural plans

Precision of manufacture in conformance with SFS5978.

View Products

- WARM LARGE ROOF REI30

- WARM ROOF REI60

- SEMI-WARM LARGE ROOF REI30

- SEMI-WARM LARGE ROOF REI60

- COLD LARGE ROOF REI30

- COLD ROOF REI60

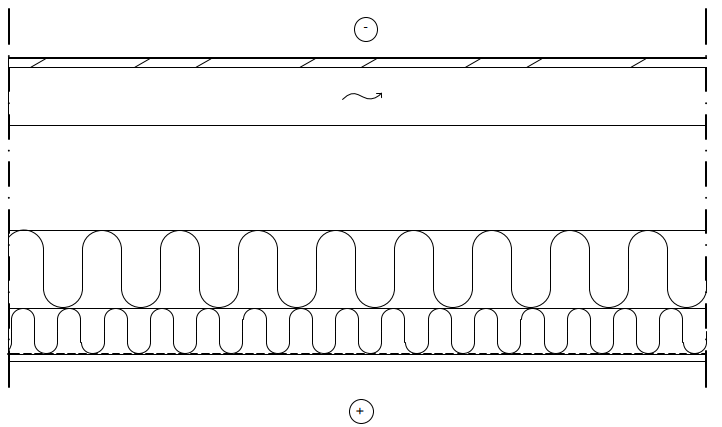

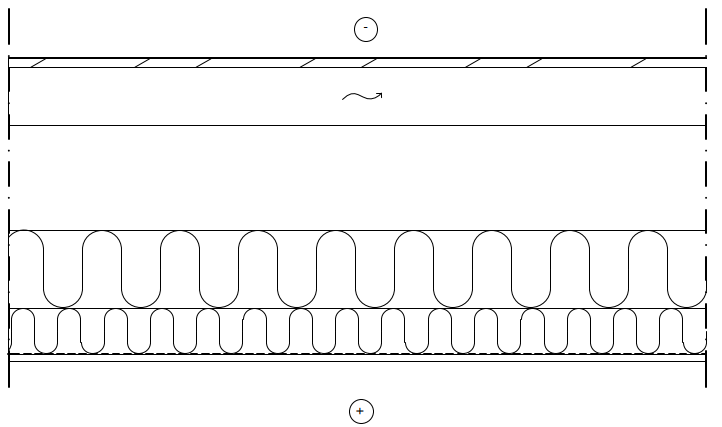

WARM LARGE ROOF REI30

A warm large roof is suitable for the construction of large roof surfaces for industrial and commercial buildings, for example. The large element, with a maximum size of 60m2, speeds up the installation and allows the building to be sheltered from the weather and warmed up quickly.

Structure:

Underlay TL2

18 mm OSB

123-148mm beams and ventilation

LVL-S load-bearing structure according to structural plans

330mm mineral wool A1

Vapour barrier (plastic)

98mm battening and mineral wool A1

15mm fire-resistant plasterboard B-s1, d0, white cardboard

Technical characteristics: U-value 0.09W/m2K, weight 0.65kN/m2, suspension load 0.30kN/m2, fire resistance REI30, maximum element size 2.7m x 25m.

Precision of manufacture in conformance with SFS5978.

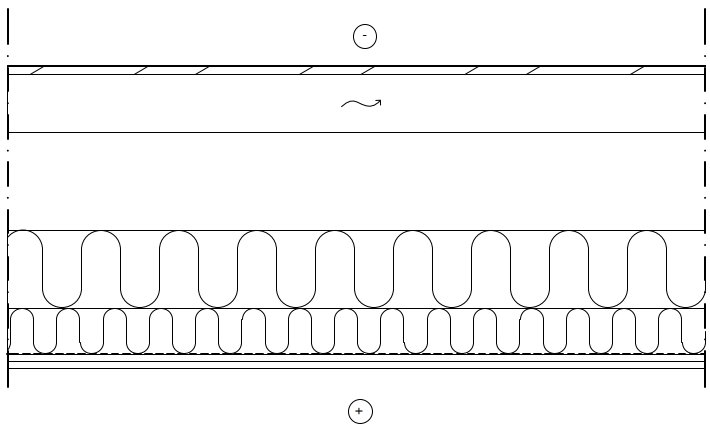

WARM ROOF REI60

A warm large roof is suitable for the construction of large roof surfaces for industrial and commercial buildings, for example. The large element, with a maximum size of 60m2, speeds up the installation and allows the building to be sheltered from the weather and warmed up quickly.

Structure:

Underlay TL2

18mm OSB

123-148mm beams and ventilation

LVL-S load-bearing structure according to structural plans

330mm mineral wool A1

Vapour barrier (plastic)

98mm battening and mineral wool A1

15+15mm fire-resistant plasterboard B-s1, d0, white cardboard

Technical characteristics: U-value 0.09W/m2K, weight 0.65kN/m2, suspension load 0.30kN/m2, fire resistance REI60.

Precision of manufacture in conformance with SFS5978.

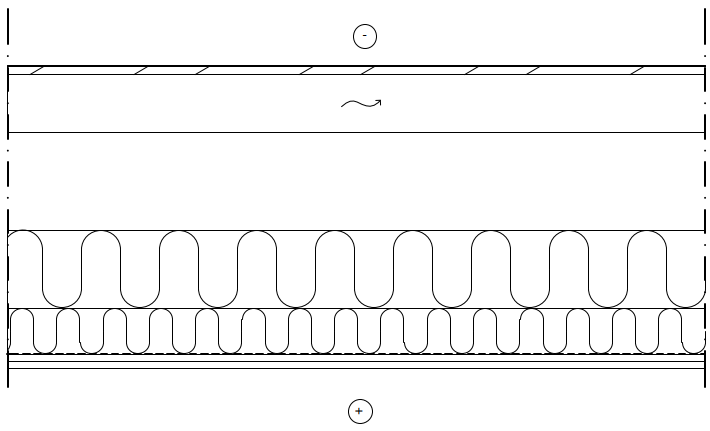

SEMI-WARM LARGE ROOF REI30

The semi-warm large roof is suitable for projects where the thermal insulation requirement of the ceiling corresponds to the U value of 0.14 W/m2K.

Structure:

Underlay TL2

18mm OSB

123-148mm beams and ventilation

LVL-S load-bearing structure according to structural plans.

165mm mineral wool A1

Vapour barrier (plastic)

98mm battening and mineral wool A1

15mm fire-resistant plasterboard B-s1, d0, white cardboard

Technical characteristics:

U-value 0.14W/mm2K, weight 0.65kN/m2, suspension load 0.30kN/m2, fire resistance REI30.

Precision of manufacture in conformance with SFS5978.

SEMI-WARM LARGE ROOF REI60

The semi-warm large roof is suitable for projects where the thermal insulation requirement of the ceiling corresponds to the U value of 0.14 W/m2K.

Structure:

Underlay TL2

18mm OSB

123-148mm beams and ventilation

LVL-S load-bearing structure according to structural plans

165mm mineral wool A1

Vapour barrier (plastic)

98mm battening and mineral wool A1

15+15mm fire-resistant plasterboard B-s1, d0, white cardboard

Technical characteristics:

U-value 0.14W/mm2K, weight 0.65kN/m2, suspension load 0.30kN/m2, fire resistance REI60.

Precision of manufacture in conformance with SFS5978.

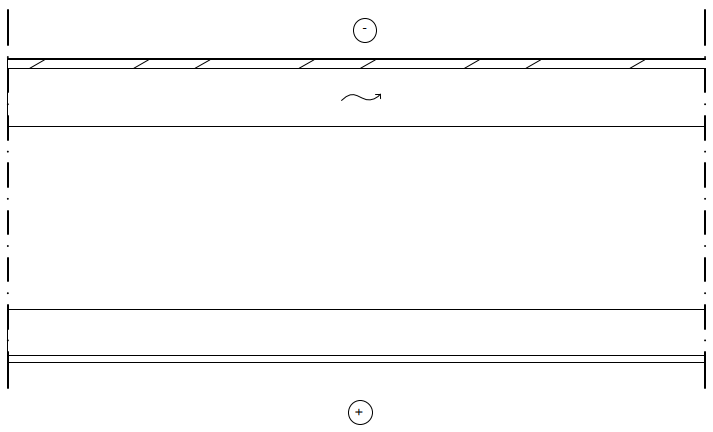

COLD LARGE ROOF REI30

The cold large roof element is used in buildings with large roofs where thermal insulation of the roof is not required.

Structure:

Underlay TL2

18mm OSB

123-148mm beams and ventilation

LVL-S load-bearing structure according to structural plans

165mm mineral wool A1

Vapour barrier (plastic)

98mm battening and mineral wool A1

15mm fire-resistant plasterboard B-s1, d0, white cardboard

Technical characteristics:

U-value 0.14W/mm2K, weight 0.65kN/m2, suspension load 0.30kN/m2, fire resistance REI30.

Precision of manufacture in conformance with SFS5978.

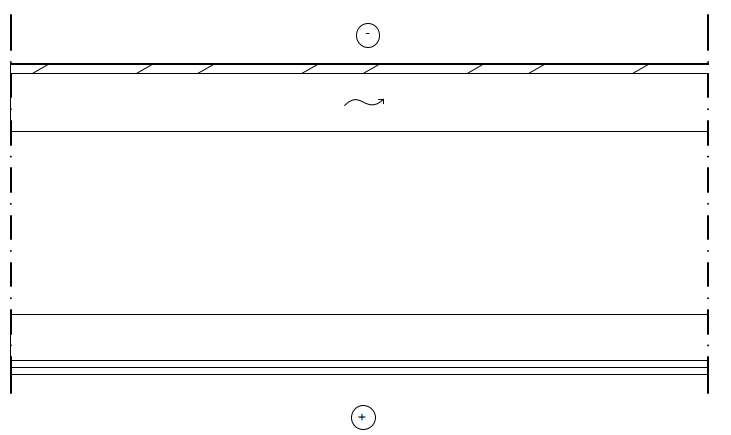

COLD ROOF REI60

Structure:

Underlay TL2

18mm OSB

123-148mm beams and ventilation

LVL-S load-bearing structure according to structural plans

Vapour barrier (plastic)

98mm battening

15+15mm fire-resistant plasterboard B-s1, d0, white cardboard

Technical characteristics:

Weight 0.65kN/m2, suspension load 0.30kN/m2, fire resistance REI60

Precision of manufacture in conformance with SFS5978.

View Products!

COLD ROOF ELEMENT KK

Katto asennetaan tukielementtien varaan kantavan betonirungon tai yläpohjaelementtien päälle.

Rakenne:

Aluskermi TL2

18 mm OSB-levy

42×123-42×198 kantava rakenne rakennesuunnitelmien mukaan

Tekniset ominaisuudet: elementin paino 0,4 kN/m2, elementin maksimikoko 2,7 m x 13 m.

Valmistustarkkuudet SFS5978 standardin mukaan.

COLD ROOF KK-LVL

The roof is installed on top of a load-bearing concrete frame or ceiling elements so that it is supported by the support elements.

Structure:

Underlay TL2

18mm OSB

42×200-51×300 LVL-S load-bearing structure according to structural plans

Technical characteristics: Element weight 0.4kN/m2, maximum element size 2.7m x 13m.

Precision of manufacture in conformance with SFS5978.

SUPPORT ELEMENT TK

Support elements are installed below the cold roof in the shape of the building’s roof. Support elements are supported on top of a concrete frame or ceiling elements.

Structure:

42×98-198 frame C24

9mm wind barrier plasterboard or sarking boards

Technical characteristics: Element weight 0.3kN/m2, maximum element size 3.8m x 12.4m

Precision of manufacture in conformance with SFS5978.

SUPPORT ELEMENT, COMPARTMENTED TK-OS

Structure:

42×98-198 frame C24

13mm wind barrier plasterboard, 1 or 2 pcs

Technical characteristics: Fire resistance EI15/EI30, element weight 0.3kN/m2, maximum element size 3.8m x 12.4m.

Precision of manufacture in conformance with SFS5978.